Special-Lite Engineers and Delivers a One-of-a-kind Storm Simulator

The University of Florida is Set to “Judge” Building Architectural Products and Entry Systems

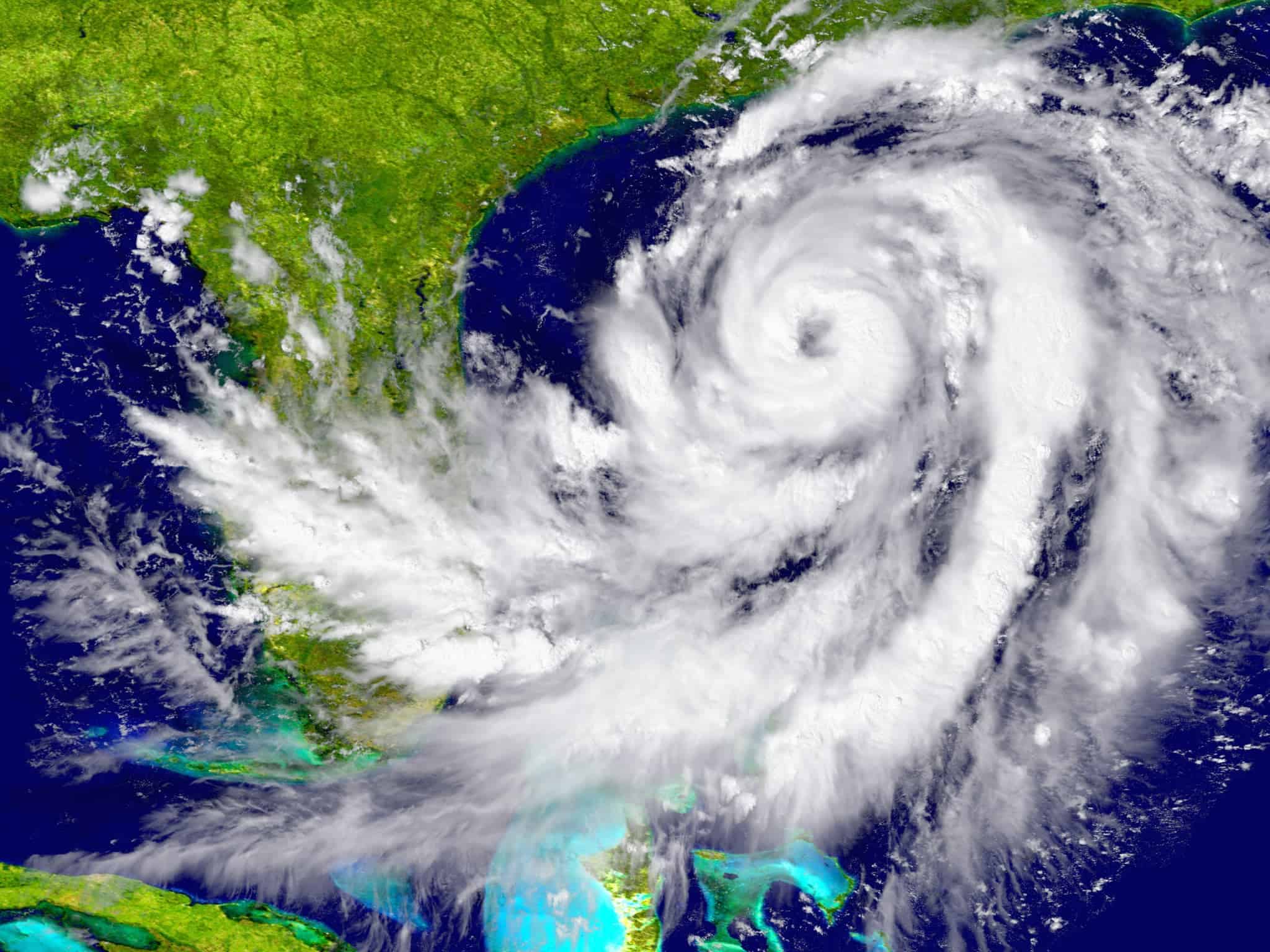

Approximately $10 billion in damage occurs in the U.S. annually due to natural events, the majority from Category 3, 4 and 5 hurricanes. In 1992, Hurricane Andrew caused more than $25B in just Dade County Florida. In 2005, Hurricane Katrina caused more than $100B in total economic loss.

In 2009, Henry Upjohn, CEO of Special-Lite, Inc., a leading manufacturer of heavy-duty entrance door systems, was approached by a business acquaintance that works with the insurance industry and routinely tours post-storm environments. This professional explained that he regularly finds instances where roll-up and sectional garage doors, built to known standards and storm ratings, were consistently failing at levels below their rating. There was a need to develop better diagnostic tools to understand how building components and claddings respond to extreme wind effects.

During that initial meeting, it was suggested that Upjohn should meet Forrest Masters, Ph.D., P.E., Associate Professor of Civil & Coastal Engineering at the University of Florida (UF). The UF wind engineering program is one of the largest of its kind in the US. The group is well known for full-scale research, i.e. performing experiments in hurricanes or replicating their effects at a sufficient scale and realism to evaluate the performance of complete building systems.

Special-Lite’s engineering team understood that property damage appeared to be most significant when building entries and windows have become compromised, often resulting in catastrophic failure. The opportunity to partner with Upjohn’s company was an ideal match as Special-Lite has built its reputation on developing engineered door entry and architectural solutions that withstand the most challenging, abusive and corrosive environments.

Upjohn and Masters met soon after and decided to build a testing apparatus capable of simulating wind and wind pressure associated with some of the most severe weather known on the planet. Conventional solutions were not up to the task, so they formed a diverse team encompassing civil, mechanical, manufacturing and industrial engineering to create a one-of-a-kind machine capable of simulating the damaging effects of hurricanes and other extreme wind events.

Conceptually, the system can be thought of as a means to replicate naturally-occurring wind and pressure caused by turbulence in the approach flow and the flow distortion around a building. For example, if a pressure sensor recorded high-fidelity data on the wall of a commercial building in Homestead, Florida during Hurricane Andrew, the simulator can “replay” this pressure sequence in its entirety. Ideally, the measured and artificially-applied load would be virtually indistinguishable.

To meet the challenge, Upjohn developed the original simulator concept design drawings, as well as personally supervised the simulator construction and assembly at the Powell Laboratory on the University of Florida’s campus. He and various members of his engineering and electrical fabrication team from the Special-Lite facility in Decatur, Michigan took many trips to Gainesville, Florida over the course of 18 months during the simulator construction.

Simulations Get Real

The new simulator (patent pending), officially referred to as the Dynamic Wind Velocity and Pressure Simulator (DWVPS) or affectionately called “The Judge”, is a unique machine that Henry Upjohn, CEO, Special-Lite, Inc. (left) with Forrest Masters, PhD., P.E. creates dynamic simulated Saffir-Simpson Scale Category 5 pressure events that produce rapidly fluctuating positive and negative pressures on a test specimen to determine at what level failure, if any, occurs.

The simulator’s primary function is to evaluate the performance of large component and cladding systems with the goal of designing better, more robust products that will endure all classes of hurricane and tornado events.

Some of the examples of use in the construction industry include testing for both sectional and roll-up garage doors, entry doors, windows, curtain walls, siding, shingles, and soffits. Other exterior components affected by extreme wind loads caused by hurricane and tornado events can also be tested.

The system operates in two modes. The apparatus has a simulation range capability of 460 psf at 70,000 cfm leakage in the pressure chamber and 230+ mph in the high-speed test section.

“We can replicate wind effects on buildings expected to occur during an entire hurricane passage,” Masters said. “A strong Category 5 hurricane is not a problem. We haven’t run a simulation yet, but I’m confident we can also simulate loads on a low-rise building in an EF4 tornado.”

The DWVPS also features a velocity simulation area which subjects smaller specimen samples (typically shingles and siding) to high-speed wind flow with rapid fluctuations.

Funding for the simulator was provided primarily by Special-Lite, with support from the Florida Catastrophic Storm Risk Management Center at FSU, the Florida Building Commission, Oak Ridge National Laboratory and the University of Florida.

“The new simulator complements multiple modeling and testing apparatuses, ranging from universal testing machines to the boundary layer wind tunnel. Its specific purpose is to apply out-of-plane loading to large-scale building components and cladding to understand how they behave under dynamic wind loading. The findings (data) are used to verify computational modeling and rational engineering analysis,” Masters said.

Test data is captured on the DWVPS with load cells, strain gauges, photogrammetry, and HD video. Deliverable data includes forces (reactions), strains, 3D displacement, and video of the entire test to identify time and degree of damage.