Why FRP?

In 1981 Special-Lite pioneered FRP face sheets in response to the need for a scratch and dent resistant door. Initially targeted at schools looking to avoid ongoing door replacements and time-intensive maintenance, this unique product has slowly proven its reliability in a variety of market applications for commercial builds and construction projects.

What Does FRP Mean

FRP stands for Fiber Reinforced Polymer. Polymer as a stand-alone is a chemical made up of repeating units. Examples in nature can include spider silk and hair. They are often lightweight, yet the unique bonding of the foundational components create varying degrees of strength, depending on the type of polymer. Another example is Kevlar, used in bulletproof vests, leaving no doubt about the power behind polymer.

Starting out with an already strong material and adding the reinforcement of fiber material(s) is what results in the face sheets that you’ll find in all of our flagship doors, as well as additional products offered. In addition to the robust strength and reliability of this material, it’s also non-corrosive and impervious to water penetration. So not only can these face sheets withstand the kicks, slams and other youthful actions within schools, they can be used in environments like wastewater treatment plants, food processing plants, power generation plants and more.

Additional Advantages

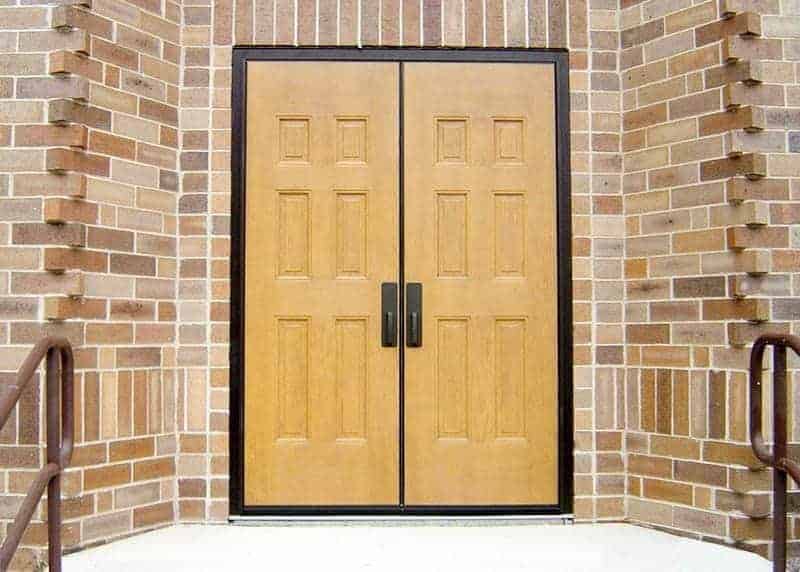

The additional advantages to FRP face sheets are the multiple possibilities of customization. They can be painted a wide range of colors, and feature a variety of looks and textures, including simulated wood grain that authentically rivals the original. Your brand can still be represented aesthetically, while also providing peace of mind regarding durability in any interior or exterior application.

Due to the tightly knit matrix of components used in FRP products they also are excellent thermal insulators. Entryways and exits are often primary sources of heat and/or cold loss and contribute directly to increased energy bills and interior temperature fluctuations. Using face sheets of reinforced material, along with other uniquely engineered features (such as our closed-cell, high-density polyurethane core, and aluminum chassis) keeps the weather out of your facility in any season.

What Fiber Reinforced Polymer Brings to your Project

FRP materials can even allow for easier installation and lower costs in construction projects. While the composition of the material allows for undeniable strength and durability, it’s also lightweight enough to replace heavier materials, such as stainless steel and other metal materials. This means easier door and panel hanging, lower-cost framing options and less stress on the interior and exterior openings.

What it all comes down to is that there is no doubt fiber reinforced polymer is a multi-faceted solution for architects, facility managers and more. If you’d like to learn more about our offerings featuring this unique component, check out the doors we offer or contact us for custom solutions.