Dealing with Humidity in Hospitality Buildings

How to Select Resilient Materials for High-Humidity Areas in Hospitality Buildings

There are many considerations for installing and maintaining doors, frames, and toilet partition products in hospitality buildings’ moisture- and humidity-prone areas.

Hospitality buildings such as hotels present several challenges when it comes to moisture and high humidity. The variety of conditions among distinct areas in these buildings combined with the high quantity of Division 8 and Division 10 products can make it challenging to choose the right products and components for each, including the fasteners used during installation.

Recognizing these areas and the challenges they present for each of the materials you can choose from is important to ensure your installation lasts and looks great for years to come.

Which Hospitality Building Areas are Prone to Moisture?

There are many high-humidity and moisture-prone areas in hospitality industry buildings, which can include:

- Indoor pool and spa areas.

- Fitness areas and showers.

- Common area bathrooms.

- Guest room entrances and bathrooms.

- Kitchen and back-of-house areas.

- Boiler and utility rooms.

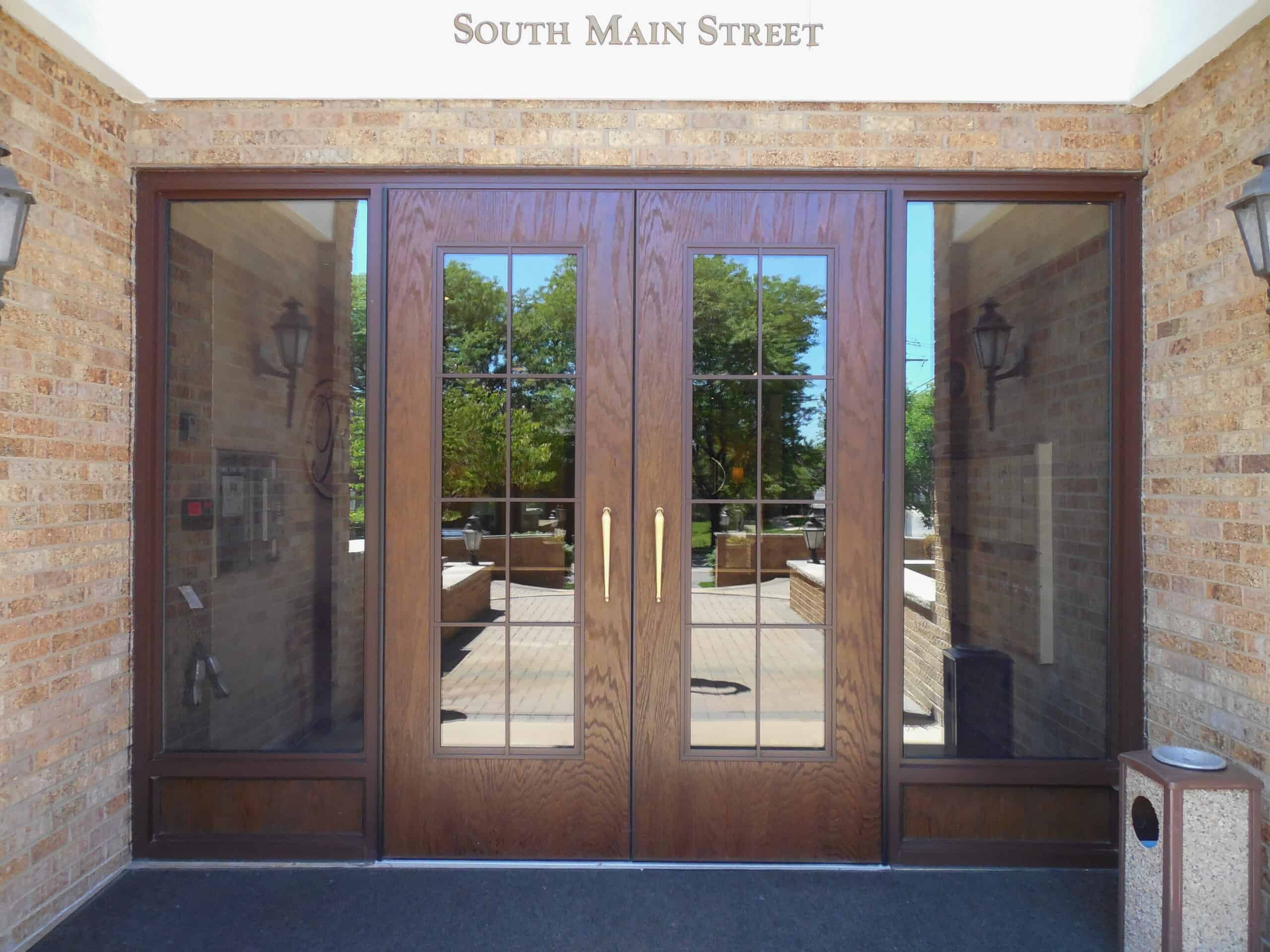

This includes the exterior for hospitality buildings in wet or humid climates, and in these climates, outdoor facilities and outdoor entrances need special consideration.

How to Evaluate if an Area Experiences High Humidity

What contributes to a high humidity area? Here are ways to evaluate and anticipate a potential humidity or moisture challenge:

- If it is a retrofit project, inspect the products you are replacing—prior products may show swelling, chipped paint, rust or other corrosion, or visible mold or mildew.

- Observe HVAC systems—ventilation is a frequent issue in hospitality buildings and is especially an issue in pool or spa areas as well as guest room bathrooms, which often lack a fan. In addition, the HVAC systems many hotels use are effective at controlling individual room temperature but are not as effective at reducing humidity levels, allowing moisture to build up in guest rooms.

- Observe fluctuations in temperature between areas—this attracts condensation.

The Moisture Problem

High-moisture areas can cause several issues with the materials we choose for partitions, doors, and frames. There are two primary ways moisture can create problems with these products:

- Retaining moisture—the presence of moisture can encourage mold, mildew and bacteria growth. Materials that retain and trap moisture are more susceptible and may additionally swell, become too heavy for hanging hardware and become permanently damaged from moisture exposure.

- Causing corrosion—water and humidity, encouraged by the presence of dust, are the key contributors to corrosion. Corrosion can take the form of surface rust, galvanic corrosion, pitting, crevice corrosion and stress corrosion cracking. Corrosion can start in hidden areas like joints, overlaps, fastener penetrations, and interiors, where it cannot be stopped.

Partitions, doors, and frames experiencing moisture and corrosion problems pose more than aesthetic concerns. The wrong materials in these applications can support mold and mildew growth, affecting the health of building occupants.

Deteriorating finishes are difficult to clean and keep sanitary. Exterior openings experiencing these issues can pose security and pest risks to the building as they deteriorate and let heating and cooling escape.

These factors can be tested for by manufacturers or component materials may have testing data available. Some of the test standards used to evaluate moisture-related issues on specific materials include:

- ASTM D3273-21: Standard Test Method for Resistance to Growth of Mold on the Surface of Interior Coatings in an Environmental Chamber

- ASTM D3274-09R21: Standard Test Method for Evaluating Degree of Surface Disfigurement of Paint Films by Fungal or Algal Growth, or Soil and Dirt Accumulation

- ASTM B117-19: Standard Practice for Operating Salt Spray (Fog) Apparatus

- ASTM D570-98R18: Standard Test Method for Water Absorption of Plastics

- ANSI/NFRC 100-2020 [E0A0]: Procedure for Determining Fenestration Product U-factors (if differences in temperature/condensation are a concern)

Problem Catalysts

Often, these same environments within the building are also subject to varying temperatures, chemicals, and cleaning and sanitizing routines that keep mold and bacteria at bay but may compound issues with corrosion, or cause additional problems with doors, frames, and bathroom partitions.

Continual direct exposure to water and pool chemicals (e.g., wet towels, swimsuits) can be a key issue in common areas adjacent to pools and spas. In addition, exterior openings that are often the first impression for guests can experience corrosion catalysts including precipitation, sea spray, dirt, road deicers and pollution chemicals.

How to Avoid the Moisture Problem in Hospitality Installations

Considerations for Product Construction

Seamless, monolithic doors, frames, and partition panels are the easiest to clean and most impervious to moisture. Minimize moisture-trapping crevices and overlapping seams. Product construction that minimizes heat transfer can help avoid condensation-driven moisture issues.

Considerations for Product Materials and Finishes

Look beyond the surface of the product to the core material. Some products are truly one piece (often called homogenous or monolithic), but some completely sealed partitions and doors have core materials that should be considered in areas prone to humidity and moisture in hospitality environments. In many cases this supposed impervious barrier will be broken with fasteners, providing an opportunity for moisture to penetrate the core material. Choosing core materials that are unable to take on moisture provides a solution to this issue. A core that avoids moisture penetration and condensation on internal surfaces is the best choice.

Resistance to harsh cleaners and chemicals, as well as ease of cleaning, are also beneficial for materials

in these environments. Regular cleaning helps keep mildew, mold, and bacteria at bay and many of the areas mentioned encounter chemicals related to their purpose, such as chlorine for pools. Avoid field painting products in these areas as moisture can affect paint adhesion. Factory-applied coatings are more suitable, and a long-lasting, durable integral finish with abrasion resistance for easy cleaning is the most suitable choice for an installation that will look great for years.

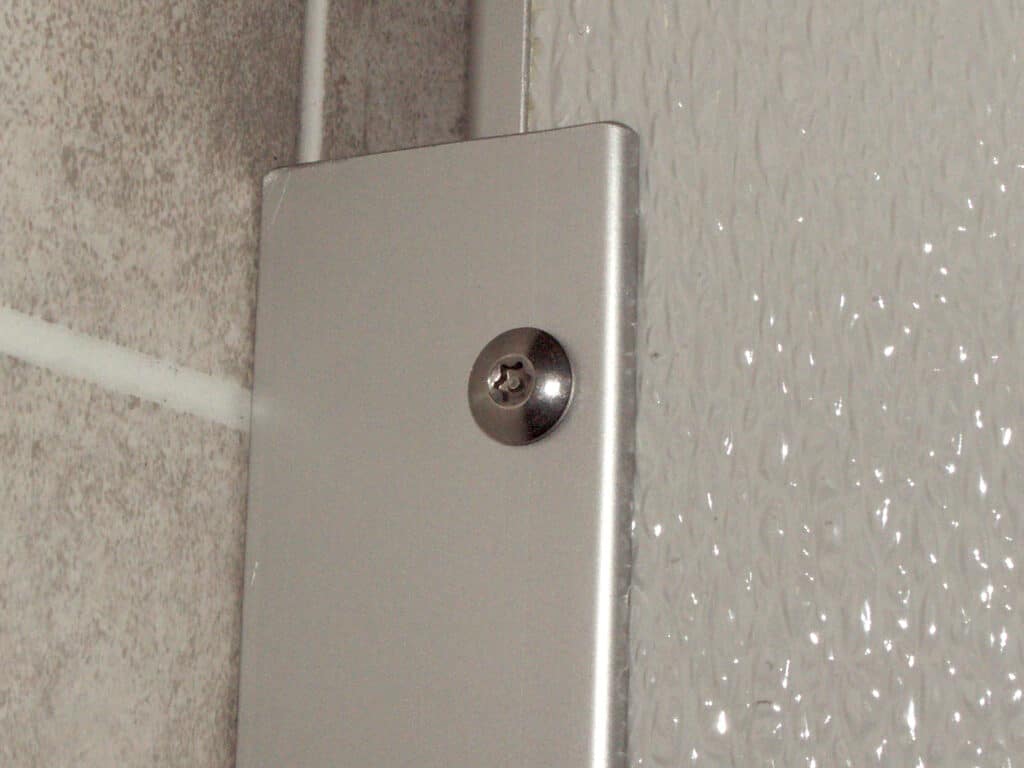

Considerations for Fastener Types

Nothing ruins a new installation of toilet partitions or doors and frames like a rusting fastener on an otherwise moisture-resistant product. Source products for a project from one source as much as possible to avoid having a variety of fastener types that may be the wrong metal for the environment. Ensure the fasteners and hardware you use are resistant to corrosion and appropriate for moisture exposure. Avoid unprotected contact between dissimilar metals.

Get started on your next hospitality building project:

-Visit our Rep Locator to find the local Special-Lite Representative in your area!

-Browse Fiberglass and Aluminum Doors, Framing Options, or Bathroom Partitions

This article was originally published in Door Security + Safety Magazine, published by DHI. View or download a PDF of the article below.

More inspiration for your next Hospitality project: